Tel00860512-83555991

The waterproof testing instrument is used for testing various outdoor products. This equipment meets the IP full series testing standards and relevant testing standards of GB, GJB, ISO, and IEC.

Online consultation

Online consultation

Support hotline:00860512-83555991

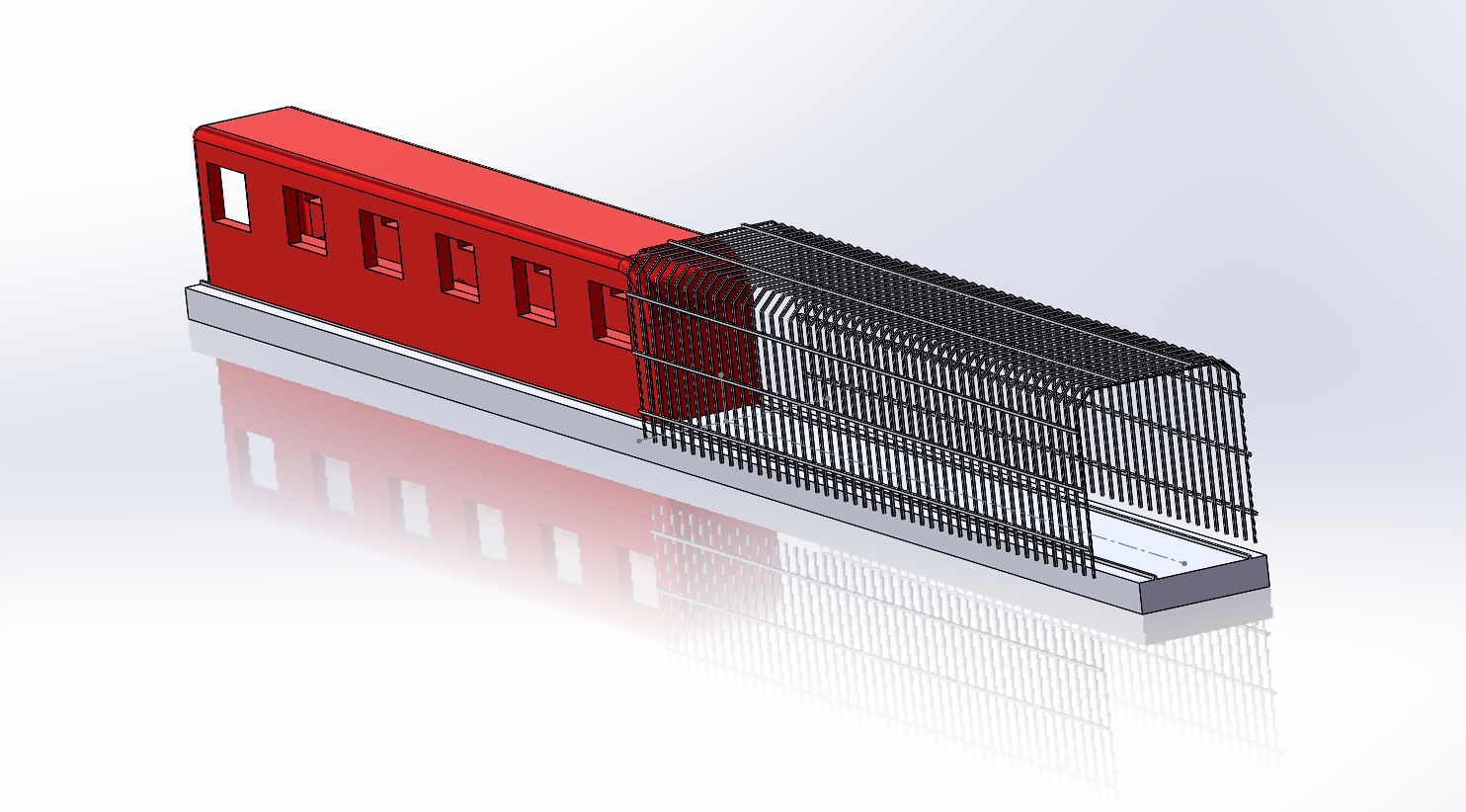

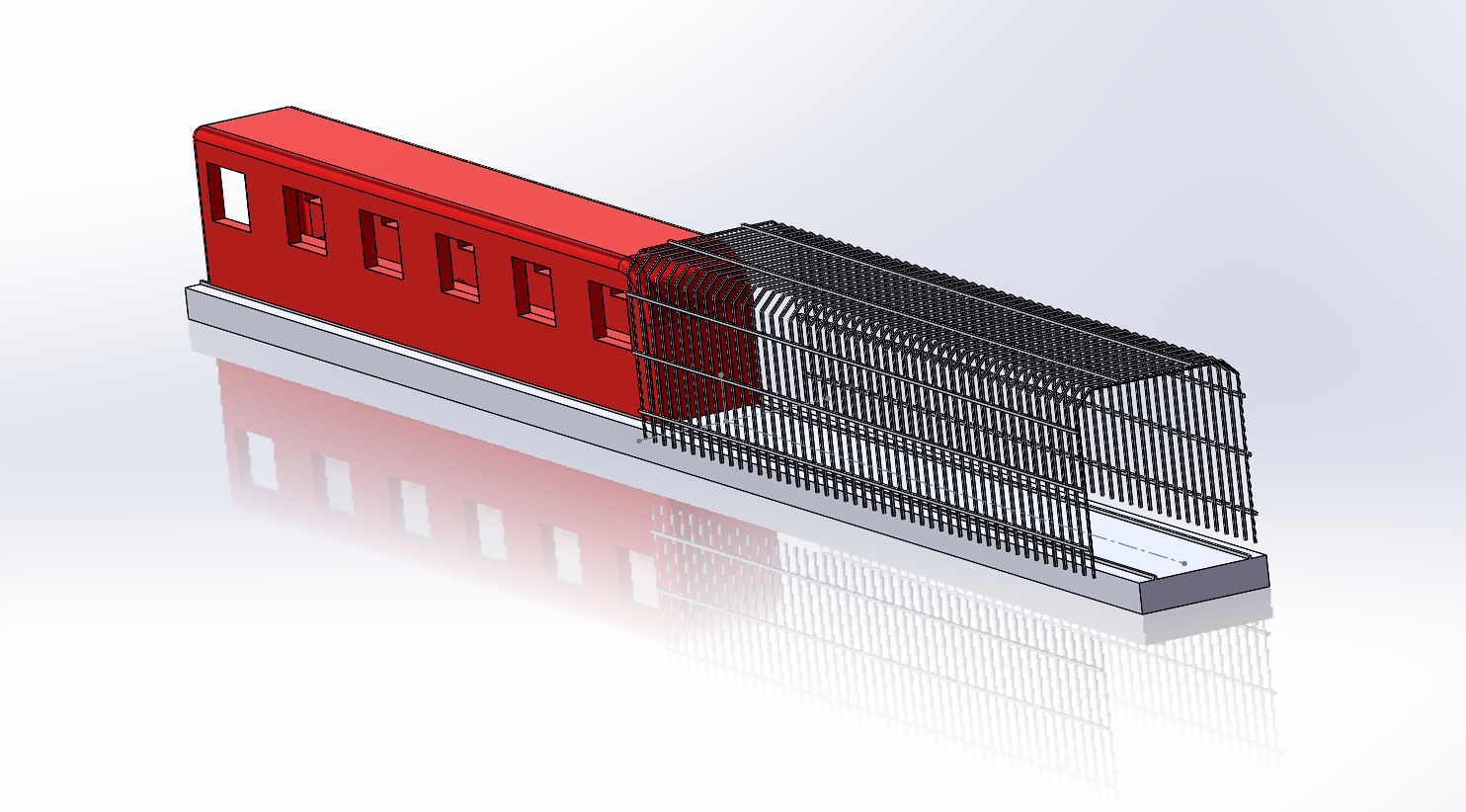

The main purpose of this laboratory test is to evaluate the ability of the tested product to prevent rainwater infiltration and its rainproof performance during or after exposure to rain Whether the roof and sides of military vehicles, small cars, and agricultural vehicles can withstand rainwater spray, whether the sealing performance is reliable, and whether the installation method is correct. Can the casing/sealing components of electrical and electronic products ensure good working performance and technical condition of the equipment and components after or during the water test

Purpose: Suitable for testing the waterproof sealing of outdoor motor vehicles. It is a device that confirms the water sealing status of vehicles by simulating the conditions of rain detection with the natural state outside through rain rooms. It is used to improve the structure of parts that may leak rain.

Pressure gauge: Install a pressure gauge at the outlet of the water pump, with a pressure range of 0-0.5 MPa. (Pressure is controlled by a frequency converter)

Flow meter: Install a flow meter after the outlet regulating valve of the water pump, with a flow rate of 1-35m3/h

Dimensions of the frame of the rain detection room (length x width x height) mm: 14000 x 4000 x 5000

Permitted vehicle size: 12500X2500X4000MM (length x width x height)

The entrance and exit doors are made of polyethylene curtain doors, with a door opening size (width x height) of 4000mm x 5000mm, and the door frame is reinforced with giant pipes.

The outer shell of the room is made of polyurethane foam insulation board, and the inner wall is made of 304 stainless steel, which is beautiful and durable. (Optional).

This device is pre designed with a return water tank in the water channel before flowing into the water supply tank, and an additional filter screen is added to filter out debris such as tape and paper entering the reservoir. A second stainless steel filter screen is installed at the inlet of the reservoir to prevent debris from entering the sewage pump of the reservoir through dual filtration. The design of the filter screen should also consider the convenience of cleaning garbage. A stainless steel filter screen should be added to the suction tank in the main pump area of the sedimentation tank, and the circulating water should be filtered before use, with a filtration level of 500um.

技术支持:腾云网