Tel0512-83555991

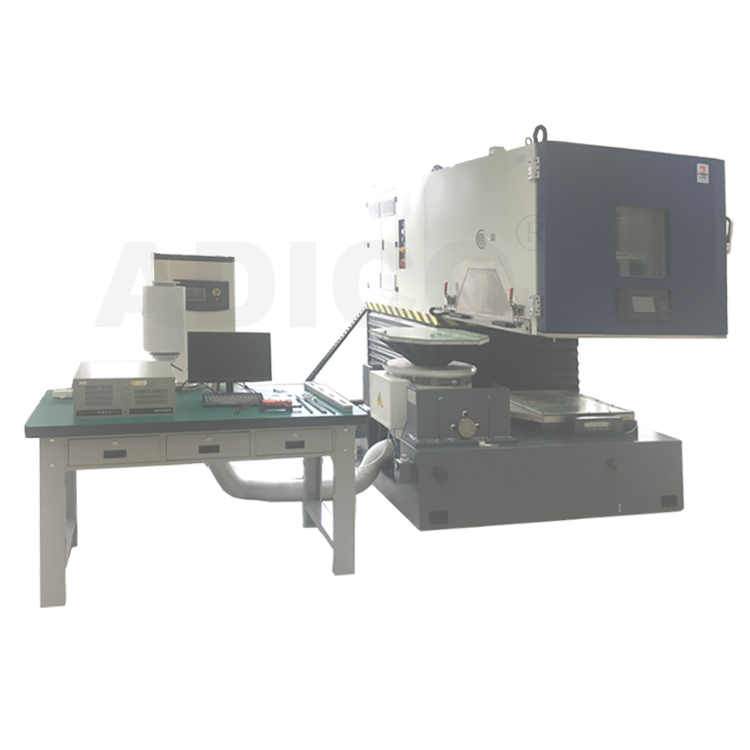

The three comprehensive test system mainly simulates the factors related to temperature, humidity, and vibration that exist simultaneously in various working conditions.

Online consultation

Online consultation

Support hotline:0512-83555991

ADICO three comprehensive equipment meets the test standards:

GBT 31485-2015 Electric vehicle battery safety requirements and related requirements for test methods;

GBT 31467.3-2015 Lithium-ion power battery packs and systems for electric vehicles Part 3: Safety requirements and relevant requirements in test methods;

QC/T413-2002, ISO16750-4 "Environmental Conditions and Tests for Electrical and Electronic Equipment of Road Vehicles";

The requirements of QC/T413-2002 on 3.11 product resistance to temperature/humidity cycle changes;

ISO16750-4 "Environmental Conditions and Tests of Road Vehicles Electrical and Electronic Equipment Part 4: Climatic Load" 5.2 temperature gradient, 5.3.1 temperature cycle with specified rate of change, 5.6 damp heat cycle, 5.7 steady-state damp heat test requirements;

IEC60068-2-1:2007 Low temperature test method Ab;

IEC60068-2-2:2007 High temperature test method Bb;

IEC60068-2-30:2005 Alternating damp heat test method Db;

IEC60068-2-78:2007 Constant damp heat test method Cab;

GJB150.3-86 high temperature test;

GJB150.4-86 low temperature test;

GJB150.9-86 damp heat test;

GJB150.3A-2009 high temperature test;

GJB150.4A-2009 low temperature test;

GJB150.9A-2009 Test standard requirements for damp heat test.

Meet at the same time

GB/T5170.2-2008 Acceptance standard for temperature test equipment;

GB/T5170.5-2008 Acceptance standard for damp heat test equipment. "JJG948-1999" Verification Regulations for Digital Electric Vibration System

"GB-T 31467.3-2015" Lithium Power Battery Packs and Systems for Electric Vehicles Part 3 Safety Requirements and Test Methods

"GB-T 31486-2015" Electrical performance requirements and test methods for power batteries for electric vehicles

technical parameter:

1. Temperature range: -75-150℃ (customizable)

2. Temperature uniformity: ≤±2℃

3. Temperature fluctuation: ±1℃

4. Temperature deviation: ≤±2℃

5. Temperature rise and fall rate: average temperature rise is 3.0°C/min; average temperature drop is 1.0°C/min

7. Temperature inner box size: width 1000mmX depth 1000mmX height 800mm

8. Humidity range: 20%~98% R.H.

9. Humidity deviation: ≤+2/-3% R.H. (humidity>75% R.H.) ≤±5% R.H. (humidity≤75% R.H.)

10. Time setting range: 0~9999 hours

11. Sine wave excitation force: 1000Kg.f peak (customizable)

Rated random excitation force: 1000Kg.f r.ms

Maximum shock excitation force: 2000Kg.f peak

12. Frequency range: 5-3000HZ; vibration isolation frequency 2.5HZ

13. Maximum acceleration: 100G, meeting customer sample test

14. Maximum speed: 2m/s

15. Maximum displacement: 51mmp-p

16. Equivalent mass of moving parts: 10kg

17. Maximum load: 300kg

18. Extended table size: 600mm×600mm (customizable)

Smoothing table size: 600mm×600mm (customizable)

19. Vibration direction: vertical up and down, horizontal front and back

20. Power requirements: AC380 (±10%) V/50HZ three-phase five-wire system

21. Test holes: two (one φ100mm hole on each side of the box)

ADICO feature introduction

(1) The key performance of the system:

◎High first-order resonance frequency and wide use frequency

Optimized design of the moving coil frame structure, especially the strengthening design of the weak links such as the traditional structure of the moving coil frame force transmission angle plate, which effectively improves the force transmission rigidity; the composite fixed winding ring barrel and the winding ring connected by glue joint and screw are adopted. The new structure of the wire loop cylinder to strengthen the glue hole enhances the rigidity of the winding. Significantly improve the first-order common vibration frequency of the moving coil, which exceeds that of similar international products.

◎High reliability of moving coil winding

The original new structure and new technology of the moving coil winding reinforcement ring significantly improve the vibration resistance of the moving coil winding in high thrust, high acceleration vibration, shock and high temperature environments.

◎High air cooling efficiency

Innovative design of the cooling air duct of the electric platform: the air inlet structure is improved, the upper magnetic ring uses a long slot type air inlet instead of a round hole type air inlet; the excitation coil adopts a honeycomb air duct, and the middle magnetic ring adopts a double-layer shunt air The new structure such as the oblique wedge-shaped air duct is adopted for the channel and the lower magnetic ring, which significantly improves the cooling effect.

◎Cooling fan

The cooling fan has a unique structure design such as air duct, the fan has good cooling effect and low noise.

◎The power amplifier adopts IGBT module

The power amplifier adopts reliable IGBT module, which has high stability and reliability.

◎Safety performance

The product meets the European standard test requirements, and the power amplifier is equipped with an emergency stop switch to effectively respond to emergencies. Comply with the safety requirements of American UL and European Union CE.

(2) The characteristics of the vibrating table body:

1. Double magnetic circuit structure: Compared with single magnetic circuit, the magnetic field is strong, the volume of the table is small, and the magnetic leakage is small.

2. Frameless moving coil: Because the moving coil frame is omitted, the active system is light in weight, has a large no-load acceleration, and the first-order resonance frequency of the moving coil is high, so that the waveform distortion of the whole frequency band is small, and the moving coil has good heat dissipation.

3. Suspension device: Roller arm suspension system and linear bearing guidance make the vibrating table have good guiding performance and better anti-eccentric load ability. Trunnion vibration isolation: when vertical vibration, special foundation can be omitted.

4. Choose air spring support with low dynamic stiffness and high static stiffness: strong load-bearing capacity and good low-frequency characteristics.

5. The moving coil of the system adopts aerospace materials (high strength and light weight), new structure, new technology, new concept (finite element design, analysis), which enhances the rigidity and strength of the moving coil, and improves the first-order axial direction of the moving coil. Resonance frequency.

技术支持:腾云网